Course Description (Excerpt)

Individual self-motivated study, research, or design project under faculty supervision. Departmental program requirement: minimum of 6 units. Instruction and practice in written communication provided.

About the Project (from proposal)

The Biomechatronics Group (Biomech) is studying the clinical effects of powered transtibial (below the knee) prostheses on transtibial amputee gait. For transtibial amputees, current ankle-foot prosthetic technology is insufficient for restoring full functionality of natural human ankles and feet. A critical anatomical component of the foot missing from prosthetic devices is the metatarsophalangeal (MTP) joint. The MTP joint is located between the metatarsal bones of the foot and proximal bones of the toes and allows for various types of anatomical motion such as flexion, extension, abduction, adduction, and circumduction in the foot. The MTP joint plays a critical role in maintaining the human body’s balance while standing and providing the push-off force for normal locomotion such as walking, running, and jumping. Current powered ankle-foot prostheses do not include a mechanical alternative to MTP joints, instead relying on a semi-rigid foot plate, therefore limiting mobility and altering the kinematics of the ankle.

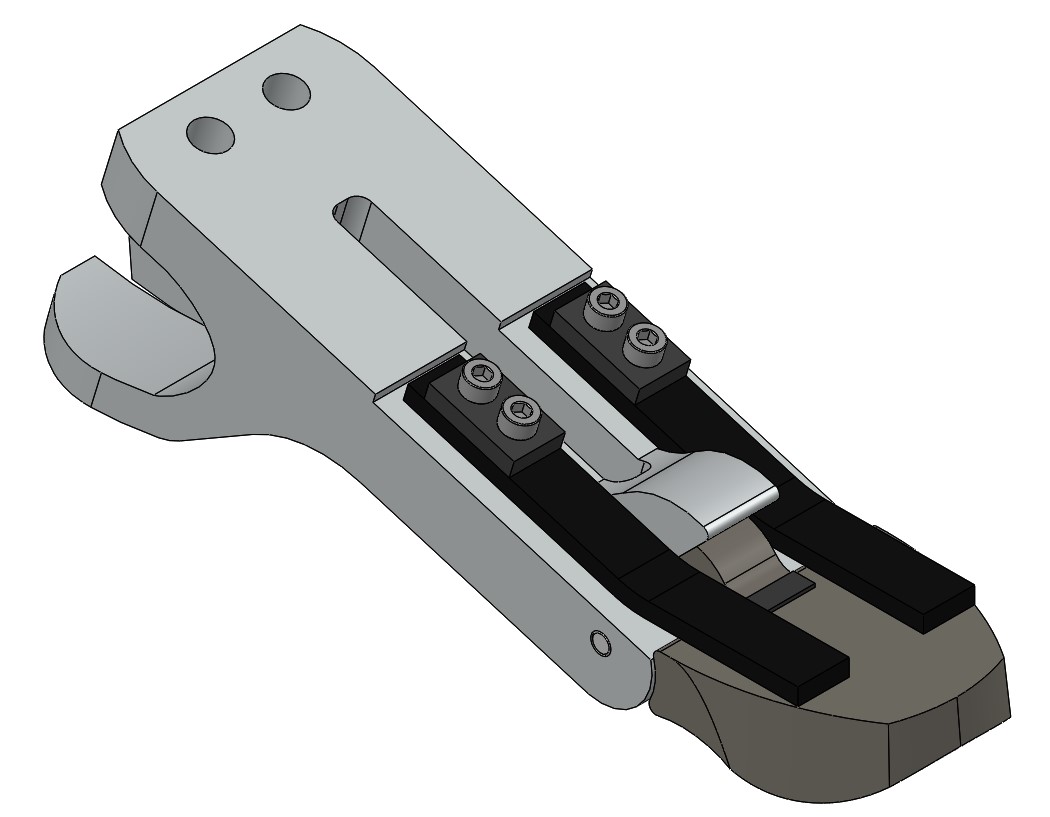

The scope of this thesis begins with designing a passive MTP joint making use of a parallel spring to support toe flexion. We are currently developing a 3D printed prototype of this model and will be testing it to inform the next steps to minimize weight as well as accommodate mechanical stresses caused by the torques acting on the MTP joint and a range of motion of up to 60° dorsiflexion. We expect the maximum torque on the MTP joint to be 1.53 Nm/deg, therefore having a maximum torque of 91.8Nm at 60° dorsiflexion. This benchmark was derived from the results of prior preliminary data collection performed by Biomech. Though this study has its limitations, their results provide us with a benchmark for our experiments.

Our goal is to design a working system that in general as light weight as possible, ideally lighter than a biological foot, while sustaining adequate loads. This design requirement requires us to maximize material utilization, so we want a design with uniform stress distribution throughout the part which can be determined by finite element analysis using software tools such as Matlab and Solidworks. We can determine that a design is successful if these design requirements are satisfied. We intended to simulate loading the MTP joint by using the Instron Universal Testing Machine in the 2.002 lab to apply a load at a known distance from the joint, allowing to calculate the torque about the joint as well as the mechanical stress and strain due to the load.

We will continue to iterate on our design with more 3D printed prototypes until we are prepared to move on to more rigid materials such as aluminum and carbon fiber. After determining that the prototype under load does not exceed the yield stress at any point, we intend to design an active MTP joint to enable control of the dorsiflexion angle.

Skills

Computer-Aided Design (Solidworks), 3D Printing, Arduino, C++, Mechanical Stress Testing, Finite Element Analysis